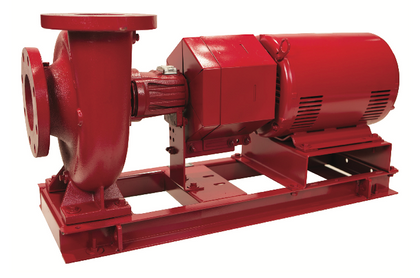

Wonders Of Bell & Gossett Series E-1510 Base Mounted End Suction Pumps

Bell & Gossett (B&G), a Xylem brand, is a leading brand for pumps, valves, heat exchangers and accessories for plumbing, wastewater and HVAC applications. For over 100 years, B&G has been an industry leader in efficiency, expertise and education. Amongst the other B&G series, the Bell & Gossett series e-1510 Base Mounted End Suction Pump offers the right need in the field of water pumping industry.

Why you should choose Bell & Gossett?

- It is a perfect piece of factory engineered package, made to fit your all requirements.

- Bell & Gossett’s Triple Duty Valve makes it give maximum protection and efficiency while minimizing equipment and installation cost.

- To give you a true pull-out service capability, the B&G series e-1510 pump provides proven performance by having a standard heavy duty welded baseplate, center dropout spacer coupling and integrally cast volute foot.

- The Bell & Gossett ESP-Systemwize computer selection program insures the precise combination of equipment for your system needs.

Features of Series e-1510

- Computer aided system sizing and selection with ESP-Systemwise makes it advanced automatic in the water pump industry.

- True back pull-out design for fast, simple and cost effective maintenance.

- Includes closed ends and open top to provide ease of access for complete grouting.

- Center drop out spacer coupling supplied as standard provides for bearing frame removal without pump or motor movement and thus maintaining the original alignment.

Suction Diffuser Plus

Bell & Gossett offers accessories to match and give the best output. The Bell & Gossett Suction Diffuser Plus is an angle pattern straightening fitting that enables the pumping system to function at the most optimum performance parameters. It conditions the flow into the pump suction to ensure the highest pump efficiency retention.

The B&G Suction Diffuser Plus includes Flow Cone, designed to eliminate the recirculation zones that develop in most suction diffuser designs available on the market today. These recirculation zones can lead to increased pressure drop across the suction diffuser and a high degree of variance in the velocity profile as flow enters the pump suction. The Flow Cone now directs the flow completely out of the Suction Diffuser and into the pump suction, providing a more uniform velocity profile that reduces uneven stress on the pump impeller and shaft. As a result pump efficiency is more effectively retained, pumping system energy costs are reduced, and the life of the pump is extended.

Features:

- 1.Completely removable internals for fast and easy maintenance.

- 2.Choice of carbon steel or stainless steel internals.

- 3.Full Length straightening vanes assure uniform flow pattern for pump inlet.

- 4.Large diameter orifice cylinder prevents debris from entering pump suction while maintaining low pressure drop.

- 5.Flow Cone eliminates recirculation zones, directing flow toward the pump, improving flow conditioning, and maximising pump efficiency retention.

- 6.Easily removable end cap with reusable O-ring.

- 7.Plug/Blow down connection permits routine maintenance.

- 8.Space saving elbow design facilitates a close transition between return piping and pump suction, eliminating the need for straight lengths of pipe and separate long radius elbows or reducing elbows.

- 9.Sizes from 2” x 1 1/2” to 10” x 10” and available with NPT or flange connections.

Triple Duty Valve

The Bell & Gossett Triple Duty Valve is a combination valve that provides all of the functions normally required on the discharge side of hydronic pump systems. The design combines three valves into one: a calibrated balance valve, a spring loaded check valve, and an isolation/shut-off valve. The combination of multiple valves helps save space and reduces installation time and money.

All Triple Duty Valves features a calibrated nameplate designed to allow you to accurately balance your system and throttle excess flow. Additionally all valves feature a memory stop or memory button to allow you to return the valve to its set position after shut-off. All B&G Triple Duty Valves also include a spring loaded check valve to prevent back-flow and gravity circulation.

Model 3DV valves utilise a calibrated ball valve design that also provides complete shut-off. The larger Model 3D and 3DS valves utilise a disc style globe valve design that also features a soft seat design that provides complete shut-off and prevents valve chatter.

Model 3DV Triple Duty Valves are manufactured with a brass body, chrome plated brass ball, and glass filled Noryl check valve with a stainless steel spring. They include two extended P/T valves and extended stem to allow for ease of installation in insulated systems, and include a choice of FNPT or rotatable flange inlet connection. They are available in sizes 1” through 2” and are suitable for up to 200 psi and 250°F. Model 3D (angle pattern) and 3DS (straight pattern) valves are manufactured with iron bodies, brass discs with EPDM seats, and stainless steel springs.

Features and Benefits:

- 1.Standard soft seal design for positive sealing.

- 2.Low pressure drop across the valve.

- 3.Flow monitoring helps you guide the flow of water according to the requirement.

- 4.Combines 3 valves in 1, saving time and money

-Calibrated balance valve with nameplate and memory stop/button.

-Spring loaded check valve.

-Isolation/Shut-off valve.

- 1.Wide range of sizes and connections:

- Straight Pattern Flanged: 2” – 14”

- Straight Pattern Grooved: 2” – 12”

- Balanced Straight Pattern Flanged: 3” – 16”

- Angle Pattern Flanged: 2” – 10”

- Model 3DV FNPT and Rotatable Flange: 1” – 2”

As a member of an industry that uses 70% of the world’s water resources, you understand that quality, delivery and management of water are critical to your success. Your bottom line depends on it and so do the health and well-being of people around the world.

Whether it’s about getting the water out of the ground or distributing it inside the plant, Bell & Gossett e-1510 comes handy in all these. These features say it all that you should get one pump for yourself too, if you want to excel with efficient faster results and reliability.

Recent Posts

-

The Bell & Gossett Ecocirc XL Pump

The Bell & Gossett Ecocirc XL Pump: Innovation in Efficiency and ReliabilityIntroductionIn the w …18th Jul 2024 -

The Efficiency of The Bell & Gossett Series e-1510 Centrifugal Pump

Bell & Gossett Series e-1510 centrifugal pumps are one of the most efficient pumps in the market …22nd Mar 2023 -

How Important Is The Bell & Gossett Expansion Tank

Bell & Gossett expansion tanks are an important component in any hydronic heating or cooling system. …20th Feb 2023